- Inspiration

- COOL! Now what?

- Theory of Operation

- Time to Paint

- Foam Insulation for Dry Ice

- Alcohol Reservoirs

- Lights

- High Voltage!

- Ready To Go

- Conclusion

Literally and figuratively speaking, this project was very cool. You can view it working here.

Over a spare weekend, I built myself a Cloud Chamber – a device that allows you to visualize ionizing radiation from radioactive sources and from the natural environment around you. With a cloud chamber, you can witness trails of condensed isopropyl alcohol vapor the follow the paths of ionizing radiation particles. You can witness alpha particles, beta particles, the residual products of gamma rays and even some remnants of cosmic rays if you’re lucky!

Since the radiation itself is invisible, this serves as an amazing way to viscerally experiment with simple particle physics.

Before I continue, I must warn that Cloud Chambers are quite a bit more hazardous than what a lot of online sources will have you believe. Dry ice, cryogenic alcohol which is also flammable, high-voltages and naturally, radioactive exposure risks if you happen to have sample sources to test. My design was pretty improvised – while it did work really well, there was a lot of design changes I would have made after the fact if I were to ever do this again. I wouldn’t recommend you recreate my exact project, but I figured I’d share what I had made anyways because this was awesome. With all this being said, if you attempt this experiment yourself, please be aware of all the risks and take all necessary precautions to keep yourself safe. This is quite dangerous and if you don’t understand or aren’t comfortable with these risks, don’t try this at home! You’ve been warned!

Inspiration

I’ve always been pretty interested in simple nuclear physics for a while now. Unfortunately, it’s not exactly a cheap hobby. Even basic Geiger counter kits were historically pretty expensive. Well, at least they used to be! Nowadays, there’s a treasure trove of cheap Geiger-Muller tube based counters out there that you can grab from Amazon and Aliexpress. Around $30 can get you a BR-6 – a dirt cheap unit with a genuine tube inside of it. Is it a bit crap and probably gives wildly inaccurate dosage readings? Yeah. Does it actually have the ability to detect ionizing radiation? Also yes!

Four screws later, and you’ll find a simple circuit board with a few power circuits, a microcontroller, a piezo beeper and a genuine Geiger-Muller tube in black heatshrink (I presume to minimize exposure to UV? Dunno if that’ll actually do anything, but neat).

BR-6 PCB. Notice the large black Geiger-Muller tube in the center. The high-voltage boost circuitry runs along the bottom-right side and up through R2 to the tube on the far right.

If you do decide to open up this unit, please be careful! There are some pretty high voltages here to charge the tube. I measured around 300V! Not recommended.

I digress…

Once you have a Geiger counter, you’ll probably want to measure something with it. Most houses actually have several small, but relatively strong sources of ionizing radiation: smoke detectors!

Not wanting to destroy my working smoke detectors, I bought one on Amazon and tore it down.

Again. I must warn you. The following is not safe and you are taking unnecessary risks if you decide to duplicate what I’ve done. Exposure to radioactive sources is dangerous, even if the source is small.

Most smoke detectors contain an ionization chamber that contains a minuscule amount of radioactive Americium 241 in the form of a tiny mixed metal foil pellet in a steel chassis. The Americium is actually Americium-Oxide sandwiched between (in my case) gold foil that helps prevent it from contaminating it’s surroundings should someone come poking at it :).

Photoelectric-style smoke detectors don’t contain a radioactive source. If you check the packaging or labeling on your smoke detector, there is a good chance that you’ll see a blurb about the radioactive source within so long as you’ve got an ionizing one.

Am-241 is primarily an alpha particle emitter, which the BR-6 cannot detect. However, Americium and it’s decay products also occasionally produce gamma rays which the BR-6 can detect. While gamma rays tend to sail right through just about everything, the fairly intense alpha particles are easily stopped by paper, gloves, glass and skin. There is less than one micro-curie of radioactive material here, which is very tiny. That being said, even though the source is small and much of the radiation can be blocked by simply wearing gloves, limiting your exposure time and showing caution is still required. Remember, this is also a source of gamma radiation. A more nuanced explanation of how safe smoke detector sources are can be found here on the U.S. Nuclear Regulatory Commission’s website. TL;DR, me handling this source briefly is fine so long as I’m cautious. I’m under no illusion that what I’m doing is safe, but I’m not eating this thing or dremeling it.

The ionization chamber opened. Notice the gold disk in the center. That is the tiny Americium 241 payload with a gold foil covering it.

Here’s a view of the source through my microscope. The Americium Oxide is contained within a golden foil sandwich. Looks pretty spooky!

As you can see from the video above, this source certainly kicks off enough gamma radiation for the BR-6 to pick up. Again, I wouldn’t trust that dose reading at all, but it is neat to see it respond to something radioactive.

COOL! Now what?

Watching the meter click a bit when I put it up against the Am source was pretty neat. That being said, this kind of detector isn’t really suitable for alpha radiation. Videos online from people that have devices capable of detecting alpha particles show their counters absolutely scream when they’re held up to smoke detector sources, so I kinda’ felt like I was missing out on the science.

There was an interesting and fairly affordable way I could actually see (visualize, I know) these alpha particles though. Build a cloud chamber!

…and so it shall be built. I took spontaneous trip to Walmart to gather an eccentric list of supplies. You know you’re doing something interesting when you get a comment from the clerk while checking out.

I didn’t really have a build plan for this thing. I just kinda’ surmised what I needed from memory under my assumptions on how this thing was supposed to work. Now that I’ve built the thing, I know what I’d do differently, but my original parts list comprised of…

2x thick metal cookie sheets. One smaller than the other so that they’d fit inside one another.

2x foam-core poster boards to act as an insulating building material that I could fit dry ice inside

1x can of flat black spray paint and a can of flat black primer

1x 5 gallon glass fish tank

1x 8 liter cooler for holding dry ice

1x cheap RGB-LED strip kit

1x LM2596 buck-converter module

1x roll of foam weather stripping (mistake. This stuff sucks and I removed it in the end)

1x electric fly swatter for generating a high-voltage field within the chamber

..and like just a bunch of stuff I had lying around like wires and a ton of 99% isopropyl alcohol (wait, you don’t keep liters of that stuff on hand?). Everything else was 3D printed.

Theory of Operation

Alright, cloud chambers are actually pretty simple.

You have a chamber. You have a sponge or felt material soaked in isopropyl alcohol inside the chamber. You have lights around the bottom of the chamber to illuminate it. The metal floor of the chamber is painted black for good visibility and is super-chilled by dry ice. You generate a high-voltage field to make it work better (ok, maybe that last one is slightly more advanced).

Anyway, the chamber becomes fully saturated with alcohol vapor. If you could imagine the weather with “100% humidity,” where the air simply can’t hold any more water, the same thing is happening here. It’s just saturated with alcohol rather than water.

That alcohol vapor isn’t able to condense throughout the majority of the chamber since the ambient temperature is too high. That’s where the dry ice and the cold metal plate come into play. The extremely cold plate allows the alcohol to condense onto it, but that’s not exactly what we’re interested in. Directly above the cold plate is a zone of ultra-saturated, cooled alcohol vapor that’s just on the cusp of condensing, but it just can’t quite make it yet. When ionizing radiation, either from a dedicated source, or from naturally decaying radioactive nuclei around you, or even the remnants from cosmic rays from space rip through the chamber, it ionizes the air. Since alcohol is a polar molecule, it becomes attracted to the particles that have become charged from the radioactive particle zipping through. This attraction rapidly causes a condensation trail to appear which is visible to us. I’m simplifying slightly, but that’s pretty much the jist of it.

Time to Paint

I began by roughing up the smaller of my two cookie sheets with some brass wool (same stuff I use for cleaning my soldering iron tips).

This was just to help the primer stick better.

I didn’t use any special metal primer, just some Rust-Oleum flat black primer. I evenly sprayed down one coat, let it dry for about 40 minutes, then put down another coat. I let that dry for about an hour.

Once it was dry, I roughed it up slightly with some scotch-bright. Just a quick once-over seemed to suffice. There’s lots of painting advice online for doing this “right,” and it usually involves much more sanding and time, but to be honest, this worked just fine and gave a perfect result.

I sprayed it down with one good layer of flat black paint and let it dry overnight. The finish looked great! You really want a perfect black stage here.

(Forgive me, I wasn’t planning on documenting most of this process, so this image was made post-experiment. Should give you an idea of the paint job, even if it was a little scuffed-up after my first run)

Foam Insulation for Dry Ice

This step was pretty easy. Since I was going to have the black cookie sheet rest upside-down, I wanted an elevated platform that would insulate the dry ice, keep it confined and also push it up into the cookie sheet. I just used some foam science project poster board for this. I measured the interior of the top cookie sheet, then created a platform with 4 layers of foam sheet hot-glued together with some guides on the side to keep everything in place. Worked surprisingly well! Styrofoam would have been my preferred choice here, but those boards were certainly easier to build with and way less messy.

Again, this shot was post-experiment, so the foam is a bit scuffed-up. (we played with the dry ice a little after, hence the dents :P)

Alcohol Reservoirs

Here’s an example where the simplest solution ended up being the better one. I had originally designed some alcohol reservoirs in Fusion 360 and had printed them out. These reservoirs were stuffed with gauze padding with a string of resistors running through them to provide enough warmth to heat the alcohol and evaporate it better. These would have probably worked, but honestly, it just seemed like a pain to wire them all up. Remember, the chamber has to be pretty air-tight and everything is exposed to some pretty nasty conditions with solvents, cryogenics, etc. Also, I didn’t want to accidentally miscalculate something and cause an alcohol fire :)

Therefore, I ditched that idea and settled for a big pad of carbon fiber felt material I had lying around. Normal felt would have probably worked fine, but I just had this stuff. I hot-glued it to the top the the tank. I did make a minor mistake here though – make sure you hot-glue all of the corners really well. My felt drooped down and dropped alcohol when it was first used which was pretty disruptive.

Lights

Pretty straightforward. I found a cheap kit of LED-light strips. They even came with their own little controller. They worked alright. I’d look for some better ones with a higher LED density next time. A more powerful, diffuse white light would have been ideal. While these LEDs do have their own adhesive on the back, I hot-glued them around the exterior of the enclosure as the alcohol surely would have dissolved the glue and wiring everything up properly within the chamber would have been a pain.

You may also notice that the bottom of the chamber has some foam weather stripping on it. This was a nice idea, but ultimately ended up being a mistake. For starters, it keep fusing itself to the paint of the black plate, making it annoying to lift the chamber off the plate. Second, it just wasn’t rated for the temperatures I was going to expose it to, therefore, when the plate deformed slightly under the temperature difference, the weather stripping stayed frozen in it’s deformed state, ruining the important seal from the outside air.

I ended up removing the foam and placing the tank directly onto the cold plate. Thankfully, my plate was thick enough to not deform all that much, so small squirts of alcohol around the perimeter of the tank during the experiment served as “surface-tension” seals. Not ideal, but worked fine.

High Voltage!

This part was pretty fun (and a bit nerve-wracking). Cloud chambers work best when they have a high-voltage potential between the observation zone and the cold plate. This voltage field dramatically improves the visibility of the vapor trails. So much so that it’s usually the difference between “it works!” and “damn it.” In our case, we directly observed that the positively charged alpha particles were strongly attracted to the negatively charged bottom plate which allowed us to toggle their visibility by turning the field on and off.

I know I’m spoiling the continuity of this story once again, but look how drastic the result is!

I achieved this high-voltage by harvesting the high-voltage step-up board from inside of a cheap electric fly swatter. $10 bucks and I had a voltage source that would make my multimeter scream OVERLOAD (sorry little buddy, I had to try it).

The circuit is actually pretty straight-forward. It appears that 3V DC comes in from a pair of AA batteries, then a small transistor circuit converts it into a high-frequency alternating current. That AC is sent through a transformer, stepping up the voltage dramatically, then through a bridge-rectifier to turn it back to DC. A big fat capacitor at the end stores the energy used for zapping flies (or you, if you’re careless). None of this really matters – I just think it’s neat!

I harvested the board from the swatter and took note of the output polarity. Fortunately, they seemed to be marked on the underside of the board. I’ve been told that the polarity doesn’t really matter in the context of the cloud chamber, but for safety reasons, I wanted the black cooling plate to be connected to the negative end of the supply. This should minimize shock-risk while in operation since the cooling plate will act as a big ground plane, shorting out any potential broken HV connections rather than applying that potential to me!

This fly swatter was also the source of the metal grate that I used to dissipate the positive charge above the cold plate.

I designed and 3D printed some simple pillars that would hold up the metal grating. They were just simple rectangular pillars with two M3 screw holes, one on each side. I also included another 3mm hole that went all the way through the pillars so I could route wires through them. I printed three of these pillars, roughly measured out their position and holes on the metal cold plate, then drilled out the holes I needed on the plate. I affixed each of these pillars to the cold plate with M3 screws, then I used more screws to hold down the metal grate. The grate actually already had a wire connected to it from the original fly swatter, so I just ran that original cable down the extra passage within the pillar it was next to. I soldered some extra wire to the bottom of the original wire, then ran that length through the bottom of the cold plate and out the side. This simple pillar design worked nicely as it provided a way to energize the grate without disrupting any seals or having cables run along the viewing area. I connected the positive end of the HV power supply to the grating. Then, I drilled a couple more holes for the negative end of the HV supply to attach to the unpainted interior of the cold plate. The negative cable had a spade connector crimped onto it and was simply attached using an M3 bolt and nut.

I wanted this entire project to run off of one power supply. Since the LEDs were going to run off of a 12V supply, I figured I’d just have to step 12V down to 3V to mimic the AA batteries that the swatter originally ran off of. At first, I used a linear regulator, but these swatters actually suck down about 500mA while running, so it made the linear regular a little too toasty. A simple, pre-made LM2596 buck converter set to 3V worked perfectly in this case. 12V->LED controller & LM2596->HV circuit->+output to grating, -output to cold plate. I simply popped open the LED controller and soldered some extra wires leeching off of the 12V barrel jack, then drilled a small hole in the enclosure to route the extra wires out.

While testing, I noticed that the transistor on the HV circuit got really hot. So hot, that the entire circuit would basically fizzle out after about 1 minute of continuous use. I suppose that this circuit wasn’t really designed to stay on for longer than just a few moments. I had some spare tiny aluminum heatsinks lying around. I thermal-epoxy’d a heatsink to the back of the transistor, let the epoxy cure overnight, and boom, no more overheating issues. It went from it’s thermal junction temperature of 150°C to only about 60°C with that little heatsink.

If you’re more prone to risk than I am, you could probably remove the bleeder resistor at the end of the circuit to maintain the charge without this thing powered on continuously, but that is a significant shock-risk since the unit will remain charged even if it’s powered down until you short it out. Same goes with the massive capacitor that’s literally designed to shock – you might be able to remove it or pick a lower value cap just to sustain the voltage but reduce the stored up energy. Make sure to use HV-rated caps! I just kept the circuit as-is.

I stuffed it all into a little 3D printed box I designed that had a set of holes on each end. Once the input and output wires were in place, I hot glued the two modules down, then used more hot glue to seal the wire holes.

Power supply. I’m using thermal epoxy to glue a heatsink onto the primary transistor on the HV circuit.

Ready To Go

That’s pretty much it! The last step I took was to attach some felt material to the top of the tank with some hot glue. This was going to be the sponge-like material to hold a bunch of alcohol and dissipate it. Should have glued down the corners a bit better as they started to droop a bit and drip alcohol during the experiment, but it wasn’t so bad.

The last component I needed was Dry Ice. I didn’t think it was going to be that hard to get my hands on dry ice, but as it turns out, it was very tricky! I called about 8 different grocery stores asking if they stocked dry ice. 6 of them did not, 1 was out of stock and the last one said they had just a tiny bit left… all the way across town. One big trip later and I had a nice chunky 7 lbs. slab. Perfect!

I drenched the felt in the chamber with 99% isopropyl alcohol. After, I seated the dry ice onto the foam. I then placed the cold plate on top of it and listened to the block loudly protest and squeal as the metal quickly cooled down.

Also, one last warning, dry ice is very cold, but it’s ability to make thermal contact things like your skin isn’t very good. It’ll still get ya’, but you have to make really good contact with it for a short time. Chilled alcohol though is like cryogenic napalm. This stuff is almost sticky in a sense and is extremely cold. You simply must wear gloves at all times as you will make contact with the alcohol when handling things. If it touches your skin, it’s almost an immediate frost-bite. With the nitrile gloves, it’s still pretty nippy, but at least it doesn’t stick to your skin and you can maneuver the glove quickly to eliminate contact with your skin. I got myself a couple times and it certainly doesn’t feel very nice – thankfully it seemed like I didn’t really sustain any real damage.

Carrying on…

Quickly, the chamber cooled. I placed a gallon bag of warm water on top of the chamber to increase the ambient temperature of the alcohol on top to help it evaporate better. Soon, waves of alcohol condensate began to form near the surface of the cold plate. Colder.. colder…

Suddenly: ZIP! ZOOM!

IT WORKED. At some seemingly arbitrary point as the plate cooled, streaming particle vapor trails zipping through the chamber suddenly became visible. Wow. I can’t believe this worked on the first try.

On our first test, we placed the smoke detector source directly onto the cold plate facing up as well as a small neodymium magnet on the off chance that we observe stray beta particles being curved by it. Immediately, you could see a small shower of particles.

After about 5 minutes though, they seemed to disappear completely. What gives? Perhaps it was the direction of the source itself? It was facing up after all. I know you can pop the little Americium button out of the surrounding chassis, but I would rather not in this case.

I made a small foil stand to hold the source roughly perpendicular to the cold plate. Yeah, you could see some particles if you looked closely enough, but it didn’t seem to be as strong as before.

In retrospect, I think the foil stand for the source was a bad idea. It likely became charged within the HV field and attracted most of the particles towards itself, preventing them from being visible in the fog.

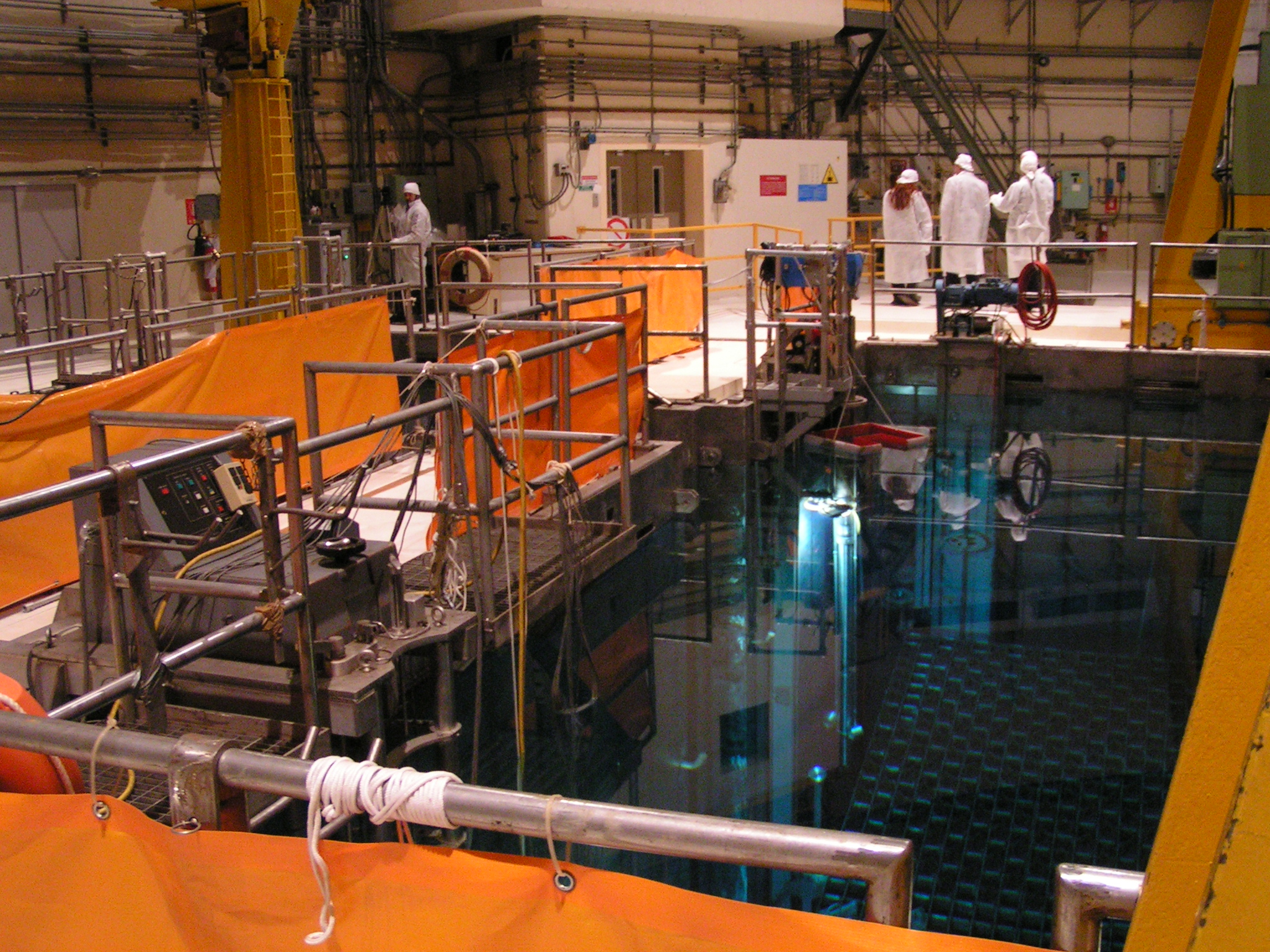

Eventually though, we discovered the big issue with why we weren’t seeing as many trails from our source. Alcohol and/or water had made it’s way onto the source, likely through condensation. Water is excellent at absorbing radiation. So much so that massive water pools are employed to shield from radiation in industrial settings like spent fuel pools and irradiators.

Image credit Simone Ramella. An example of a spent-fuel pool filled with water to cool spent nuclear fuel and to shield workers from radiation.

In our case, the alpha particles had so much trouble making their way through whatever liquid was covering our source that a nearly imperceivable drop of it was preventing us from visualizing anything. After drying-off our source, alpha particle vapor trails immediately became visible again. Awesome!

What followed next was an amazing example of organic discovery. I still wanted the source’s output to be facing the cold plate, but I didn’t want to involve my crude foil stand anymore. So, I just placed the source face-down on top of the HV grid.

Instantly, we saw a massive shower of particles. This was the absolute best result we had seen so far. You could clearly see a huge plume of particles emanating from this tiny source. This was quite impressive for an alpha source as alpha particles tend to only travel a couple inches or so before being absorbed.

Conclusion

This project was mesmerizing and very satisfying to build. I found it fairly simple to throw together and was shocked at how well it worked on the first try. I could have watched it all night.

If I were to try this again, I’d go with a far smaller scale. The size of the chamber was pretty neat, but at the end of the day, it’s a big, bulky thing that I now need to find space for. I’d also like to avoid using dry ice again. As fun as dry ice is to play with, it was a major pain to find and was inconvenient to transport. I’d like to try this again one day with a much smaller design that uses peltier elements and a large heat sink instead. Peltier elements, despite being fairly inefficient, can transfer enough heat to create the cryogenic temperatures needed for a device like this. With the right design, all I’d need to do is add some alcohol, flick a switch and boom, things get cold and vapor trail-y.

The small scale would also make it easier to create a more robust seal as it means less chance for metal plates to dramatically flex under the temperature difference.

Next up, I’ll be exploring some fairly simple gamma ray spectroscopy with a new device I have coming in soon. The Radiacode 103. This device uses a scintillation crystal instead of a geiger-muller tube to detect gamma rays. While this device is far more expensive than my dinky BR-6 geiger counter (by an order of magnitude lol), it is far more sensitive and far more capable. This tool will allow me to identify radioisotopes based on their energy signatures, measure radiation intensity with far more precision and even log ambient levels of radiation on a map. Super cool! Can’t wait to try it out.